Class 2 Div 2 LED Lighting: Why Rugged Matters for Light Fixtures

Industrial settings need the right lighting to accomplish a variety of functions, from checking for surface blemishes on stamped parts to ensuring no drips, inconsistencies, or overspray take place in the paint booth. The challenge is intensified by the harsh conditions such lighting fixture face in day-to-day operation.

The fixtures need to operate in toxic environments that can be prone to vibrations. The traditional solutions to industrial lighting issues have historically involved incandescent lighting, fluorescent lighting, and light-emitting diode (LED) lighting. Each has strengths and weaknesses.

- Incandescent lighting: Known for emitting a “warm” light that people find attractive, incandescent lighting is nonetheless the most delicate of the three technologies, both in terms of lifespan and resistance to rough service. They are also the least energy-efficient and are rarely used in industrial applications.

- Fluorescent lighting: Fluorescent lighting is more energy-efficient than incandescent lighting, offering an up to 35% increase in energy efficiency. They last longer and generate less heat in operation. However, they can also undergo color shifting, and they contain toxic materials like mercury and phosphorus that make safe disposal a challenge.

- LED lighting: LED lighting is rapidly replacing fluorescent solutions because it outperforms the latter in critical ways. It is over 40% more energy efficient, has a longer lifespan (50,000 hours), provides full brightness immediately, is more environmentally friendly, and enables better color representation. LED lights are initially more costly than fluorescent lights but can be more cost-effective due to their longer service life and better energy use profile.

In A Class Where Ruggedness Matters

eLumigen’s LED lighting delivers all the benefits mentioned above, along with an additional critical feature: Class 1 Division 2 (C1D2) certification. This classification, governed by the National Electric Code (NEC) and Underwriters Laboratories (UL), sets safety standards for hazardous environments.

C1D2 guidelines categorize locations based on the likelihood of flammable or explosive substances being present. Specifically, they certify LED fixtures for use in areas where flammable gases, liquids, or vapors may occur occasionally under abnormal conditions. This makes eLumigen’s lighting ideal for paint booths, stamping departments, and other inspection-intensive applications.

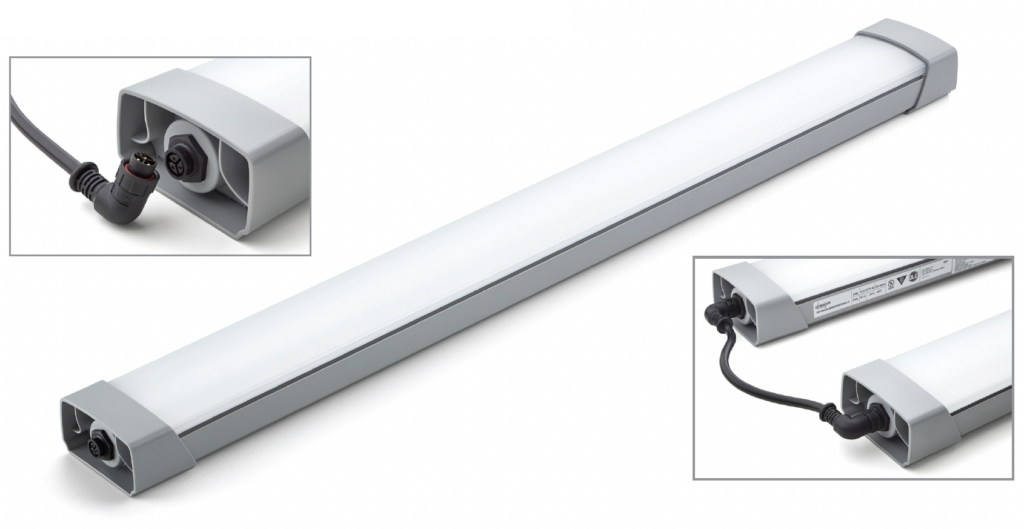

Beyond its rugged construction, our High CRI C1D2 Hazardous Location LED fixture boasts a 95 Color Rendering Index (CRI) rating – a measure of how accurately a light source reveals true object colors. This dual advantage of durability and exceptional color clarity makes it perfect for applications requiring precise visual assessment. The fixture serves as an efficient replacement for standard 4 ft × 8 ft linear fluorescent lights and includes an integrated connector cable for simplified installation.

To learn more about eLumigen and its rugged High CRI C1D2 Hazardous Location LED fixtures, call (855) 912-0477 or contact us.